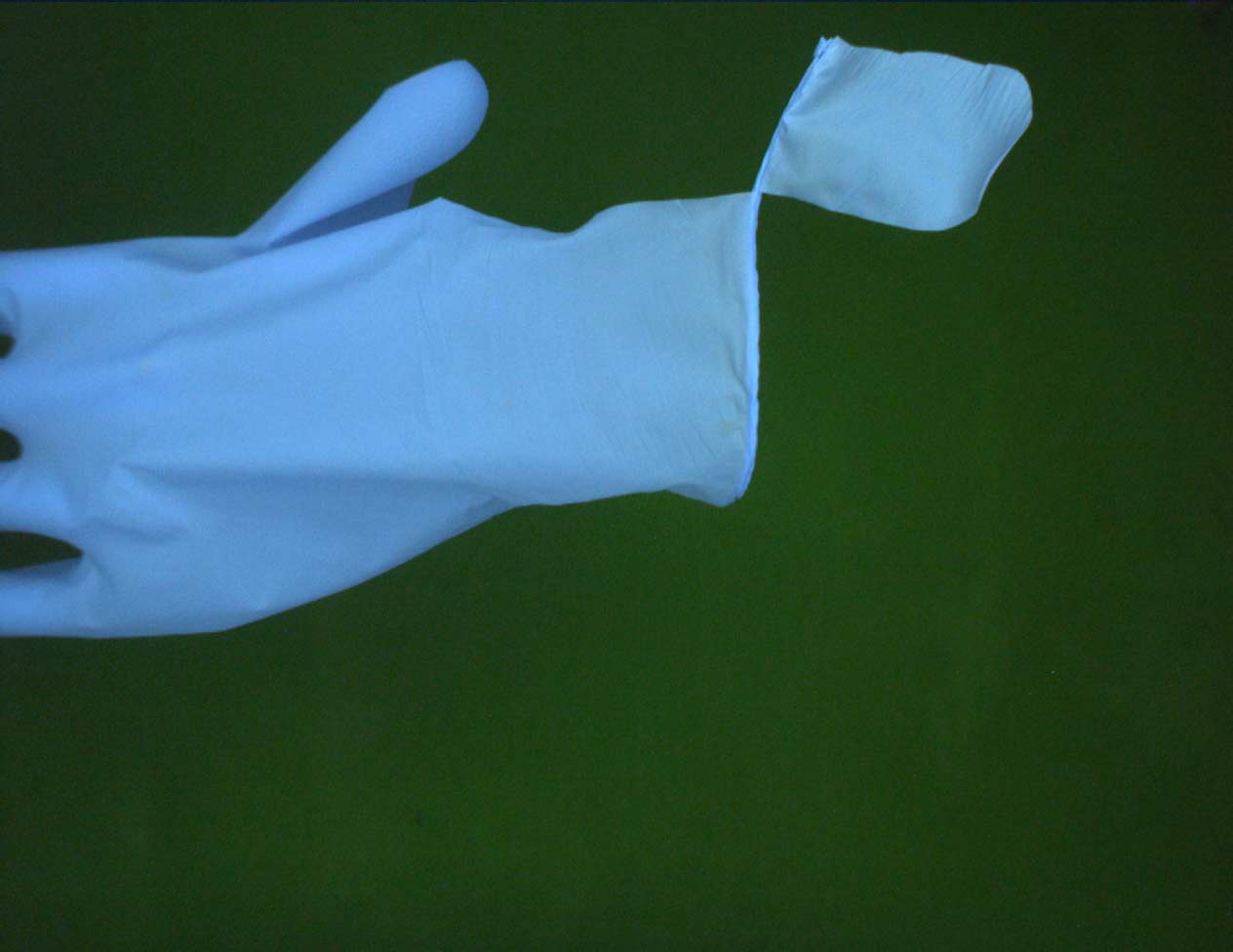

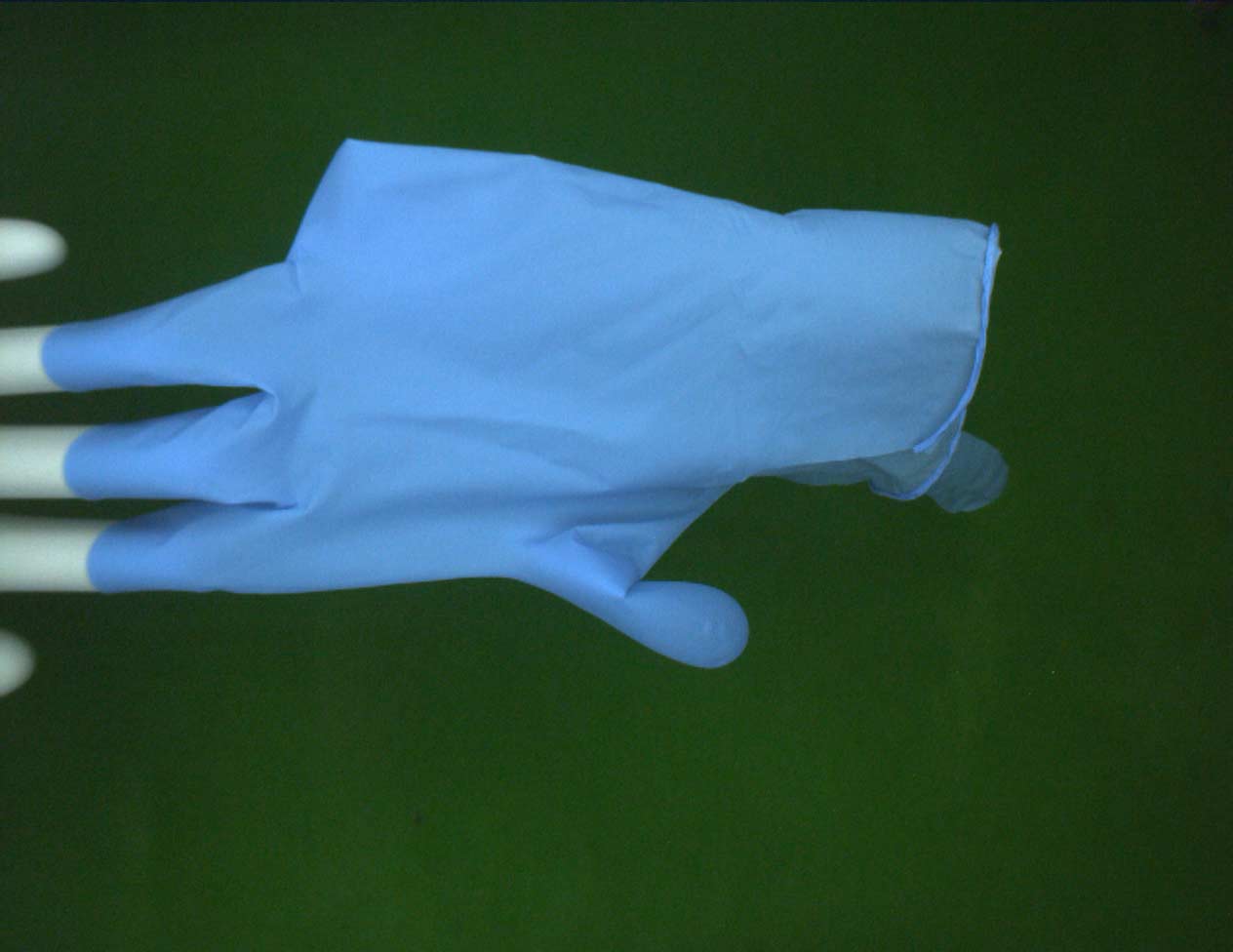

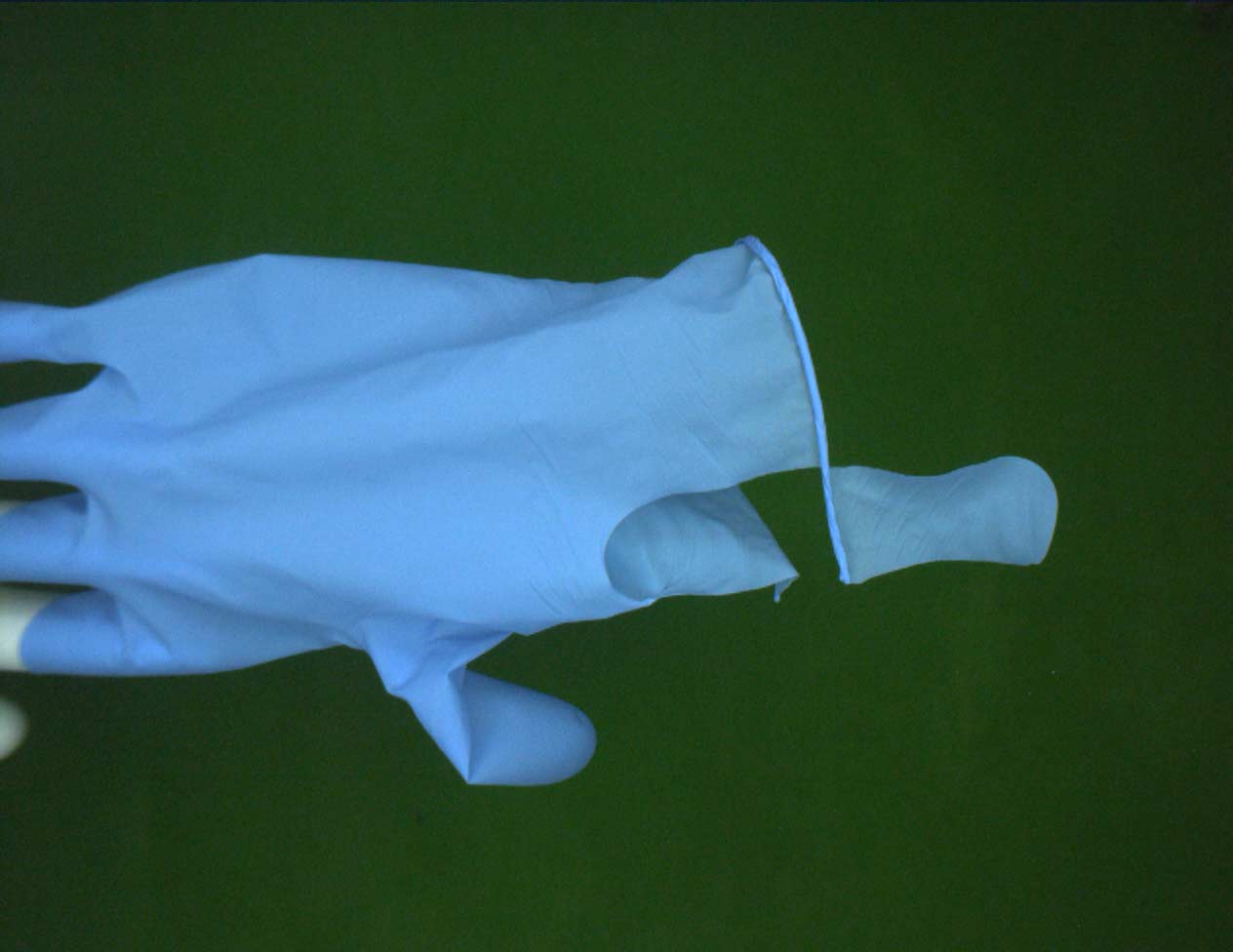

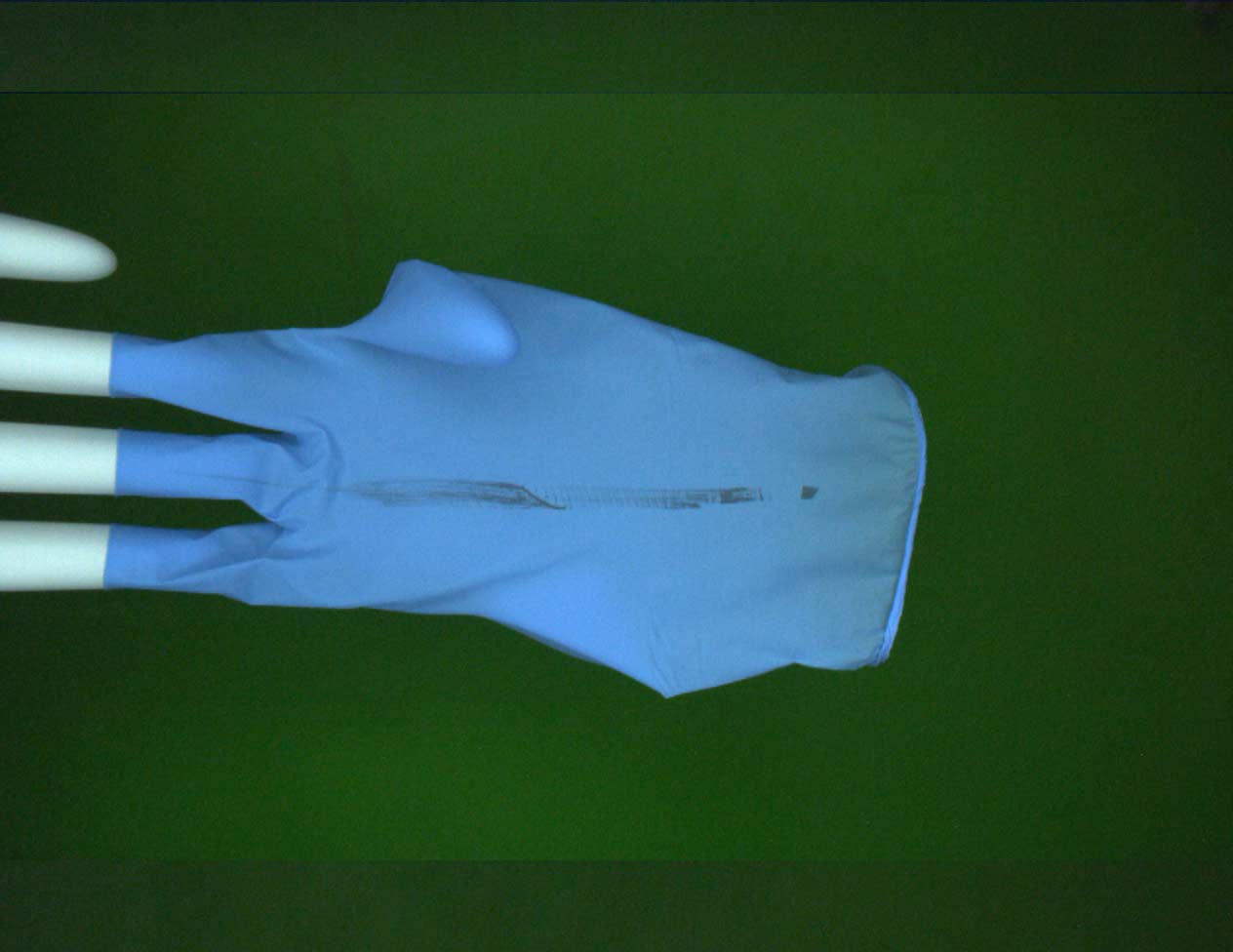

Bimodal line

During the movement of the gloves, the high-speed camera completes the shooting, and the collected images are uploaded to the host computer for image preprocessing and then sent to the Deep Learning model for inference. The results of the model inference are sent to the system to classify the gloves into qualified or defective categories. . The equipment does not take any measures for qualified gloves and releases them to the counting machine for packaging; for defective gloves, the control system automatically controls the rejecting machine and counting machine to remove the defective gloves.

Machine vision

Machine vision 轴承滚子

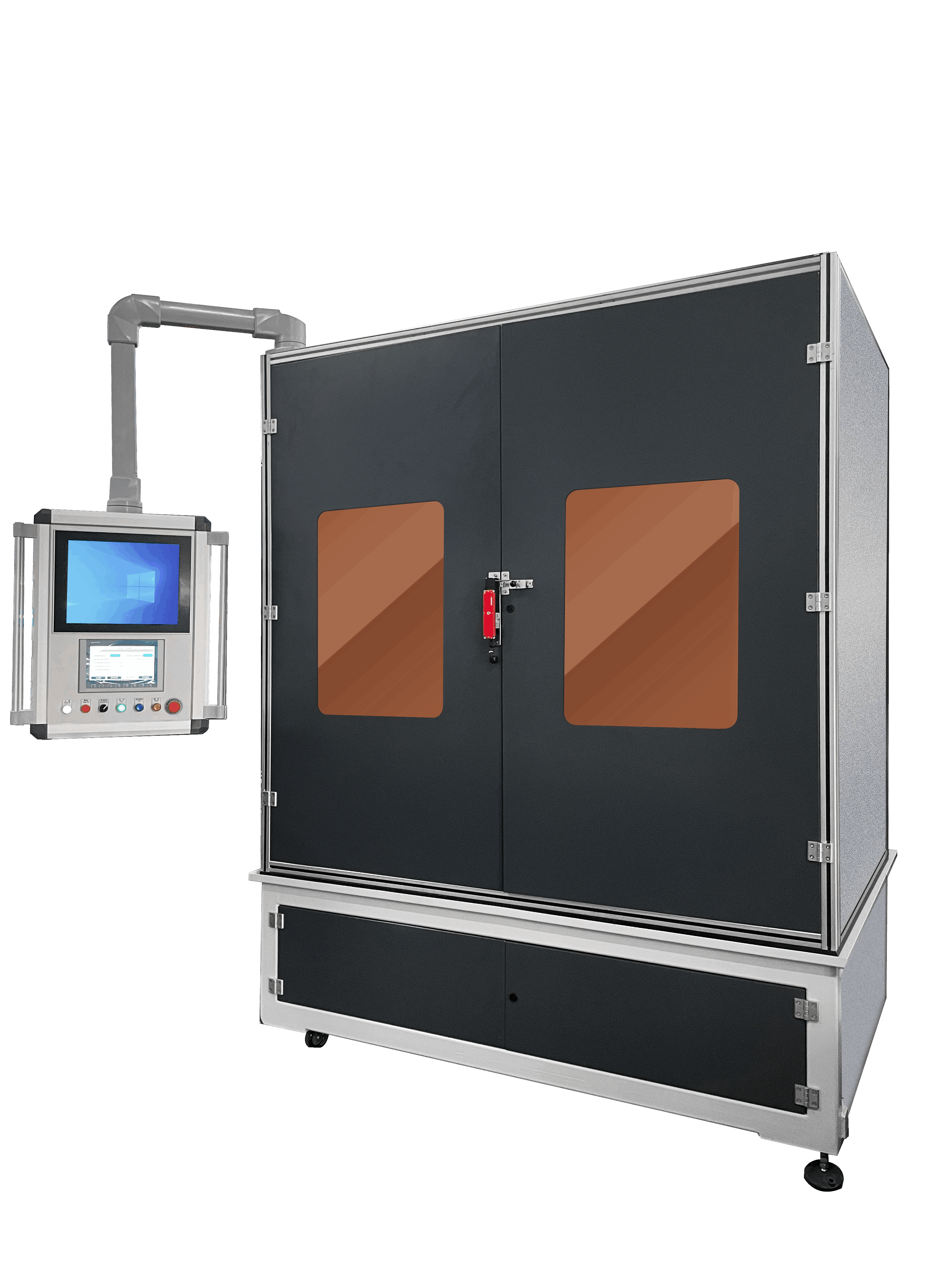

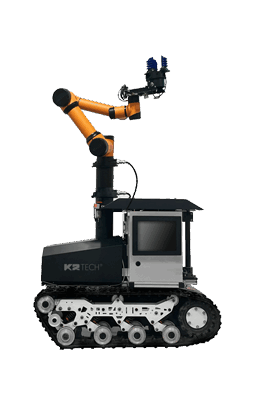

轴承滚子 Enameled wire 滚针外观缺陷光学自动检测设备(Choyo-R21) Robot for Optical Automatic Detection of Large Roller Appearance Defects Aligning roller轴承外观缺陷光学自动检测设备 超Robot for Optical Automatic Detection of Large Roller Appearance Defects 套圈外观缺陷光学自动检测设备 轴承防尘盖外观缺陷光学自动检测设备 轴承成品外观缺陷光学自动检测设备 钢球外观缺陷光学自动检测设备 滚子自动上料机 滚子在线雾化涂油机 滚子在线清洗烘干机

Enameled wire 滚针外观缺陷光学自动检测设备(Choyo-R21) Robot for Optical Automatic Detection of Large Roller Appearance Defects Aligning roller轴承外观缺陷光学自动检测设备 超Robot for Optical Automatic Detection of Large Roller Appearance Defects 套圈外观缺陷光学自动检测设备 轴承防尘盖外观缺陷光学自动检测设备 轴承成品外观缺陷光学自动检测设备 钢球外观缺陷光学自动检测设备 滚子自动上料机 滚子在线雾化涂油机 滚子在线清洗烘干机