National defense

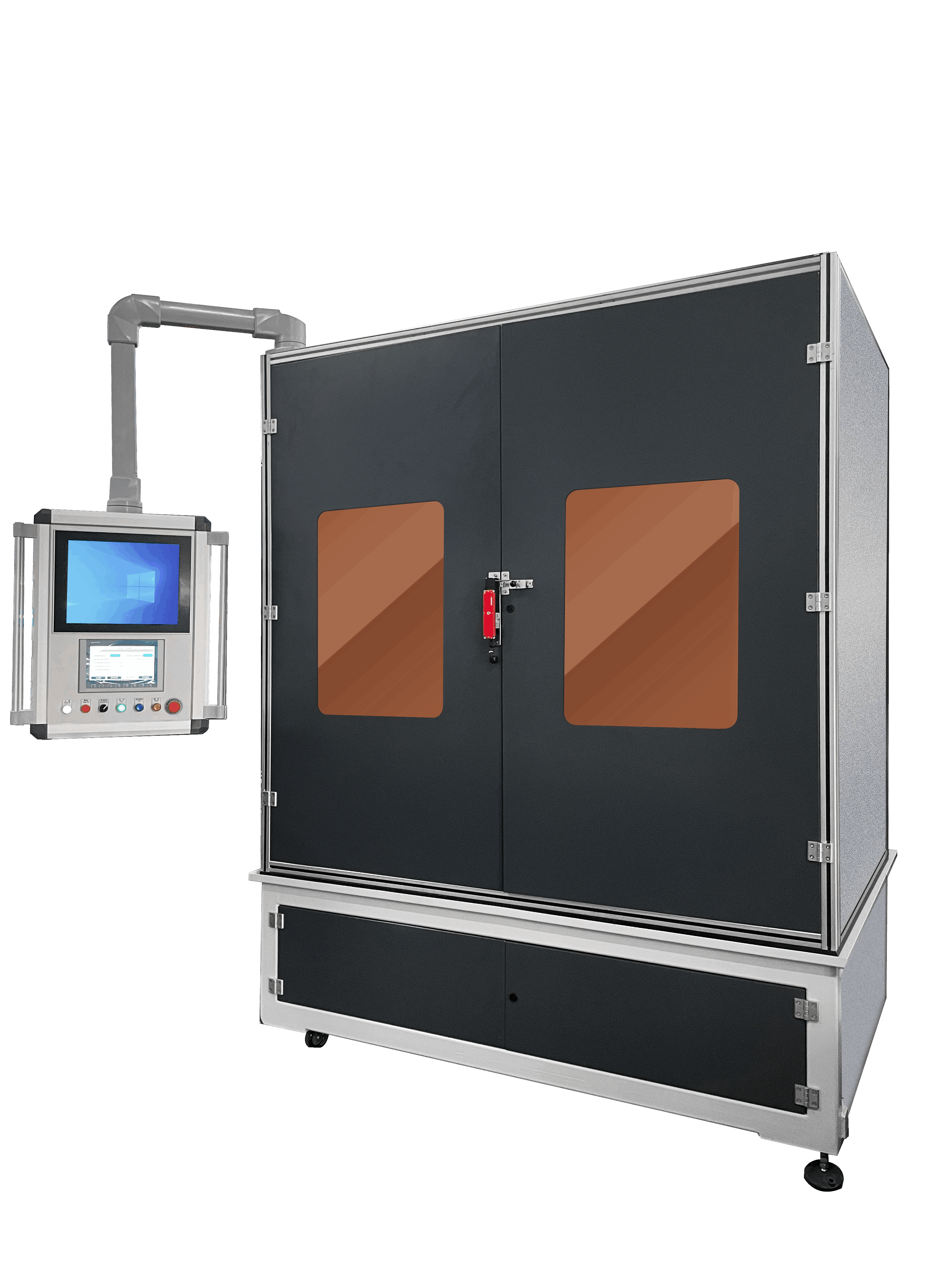

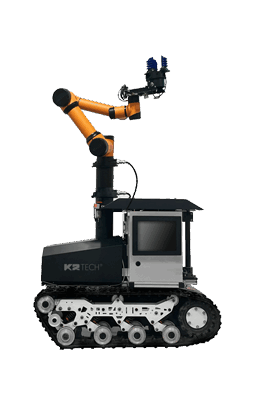

Since its establishment, Caton&Hera Technology has successfully developed intelligent testing equipment for multiple industries, solving quality testing problems in the manufacturing process for customers including aerospace groups, aviation groups, military enterprises, many large listed companies and foreign-funded enterprises. One device can meet the needs of various complex detection applications. Equipment can be customized according to customer needs, including various flexible options such as vision, detection, identification and positioning, robot control, etc. Advanced functions can be obtained by simply upgrading the software.

Machine vision

Machine vision 轴承滚子

轴承滚子 Enameled wire 滚针外观缺陷光学自动检测设备(Choyo-R21) Robot for Optical Automatic Detection of Large Roller Appearance Defects Aligning roller轴承外观缺陷光学自动检测设备 超Robot for Optical Automatic Detection of Large Roller Appearance Defects 套圈外观缺陷光学自动检测设备 轴承防尘盖外观缺陷光学自动检测设备 轴承成品外观缺陷光学自动检测设备 钢球外观缺陷光学自动检测设备 滚子自动上料机 滚子在线雾化涂油机 滚子在线清洗烘干机

Enameled wire 滚针外观缺陷光学自动检测设备(Choyo-R21) Robot for Optical Automatic Detection of Large Roller Appearance Defects Aligning roller轴承外观缺陷光学自动检测设备 超Robot for Optical Automatic Detection of Large Roller Appearance Defects 套圈外观缺陷光学自动检测设备 轴承防尘盖外观缺陷光学自动检测设备 轴承成品外观缺陷光学自动检测设备 钢球外观缺陷光学自动检测设备 滚子自动上料机 滚子在线雾化涂油机 滚子在线清洗烘干机