-

Product

Machine vision

Machine vision 轴承滚子

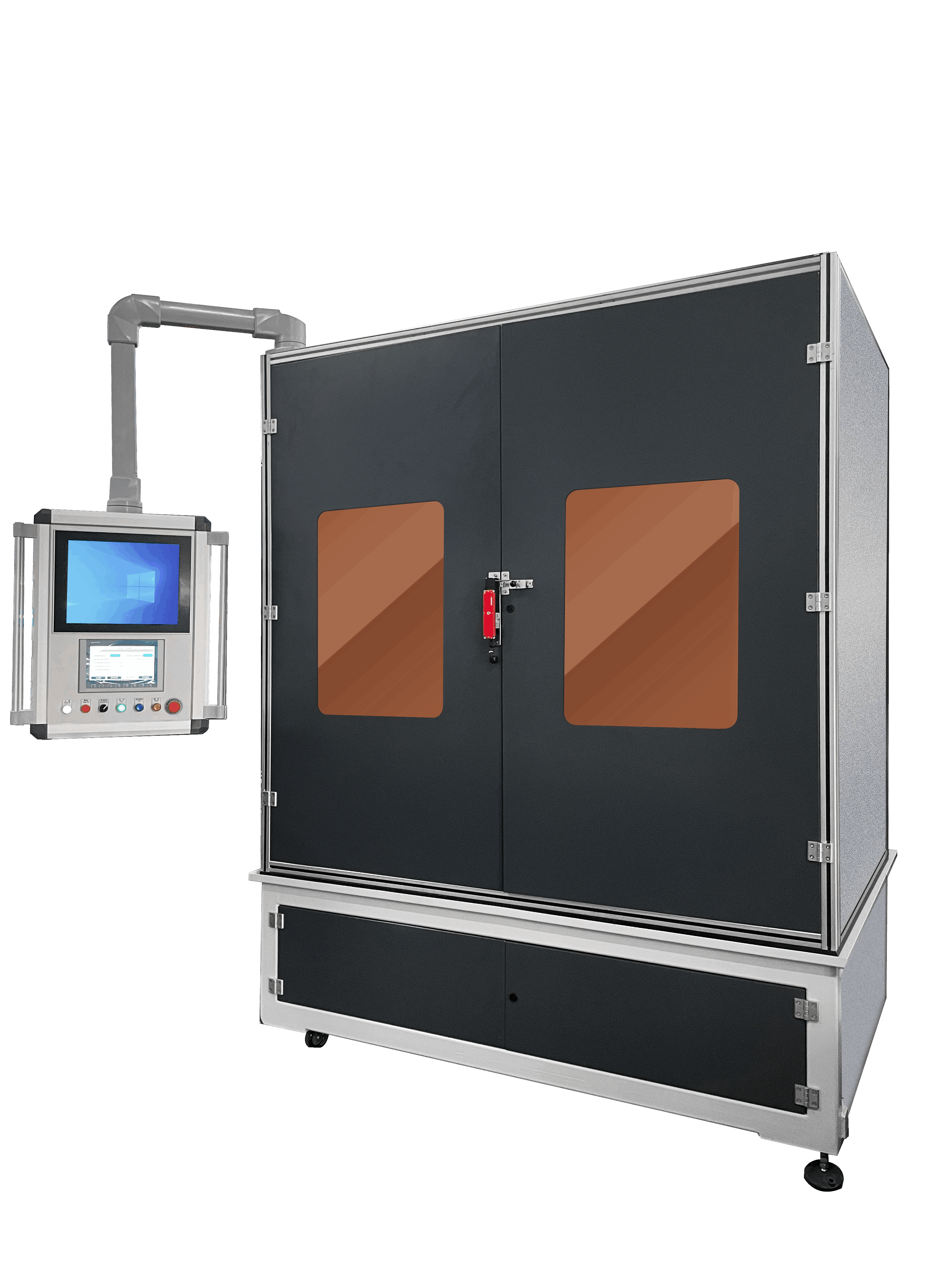

轴承滚子 Enameled wire 滚针外观缺陷光学自动检测设备(Choyo-R21) Robot for Optical Automatic Detection of Large Roller Appearance Defects Aligning roller轴承外观缺陷光学自动检测设备 超Robot for Optical Automatic Detection of Large Roller Appearance Defects 套圈外观缺陷光学自动检测设备 轴承防尘盖外观缺陷光学自动检测设备 轴承成品外观缺陷光学自动检测设备 钢球外观缺陷光学自动检测设备 滚子自动上料机 滚子在线雾化涂油机 滚子在线清洗烘干机

Enameled wire 滚针外观缺陷光学自动检测设备(Choyo-R21) Robot for Optical Automatic Detection of Large Roller Appearance Defects Aligning roller轴承外观缺陷光学自动检测设备 超Robot for Optical Automatic Detection of Large Roller Appearance Defects 套圈外观缺陷光学自动检测设备 轴承防尘盖外观缺陷光学自动检测设备 轴承成品外观缺陷光学自动检测设备 钢球外观缺陷光学自动检测设备 滚子自动上料机 滚子在线雾化涂油机 滚子在线清洗烘干机 -

Solutions

-

About Us

-

Service support

- Contact us

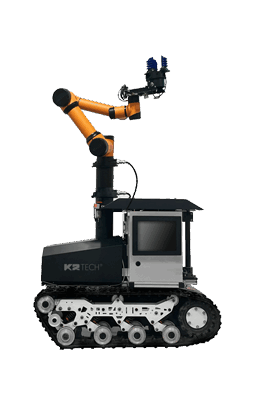

There is no need to set points in advance, and the robot arm can be controlled in real time to go to different points through calculation.

The vision system identifies obstacles and the robotic arm automatically avoids them.

Meet flexible production.

There is no need to set points in advance, and the robot arm can be controlled in real time to go to different points through calculation.

The vision system identifies obstacles and the robotic arm automatically avoids them.

Meet flexible production.