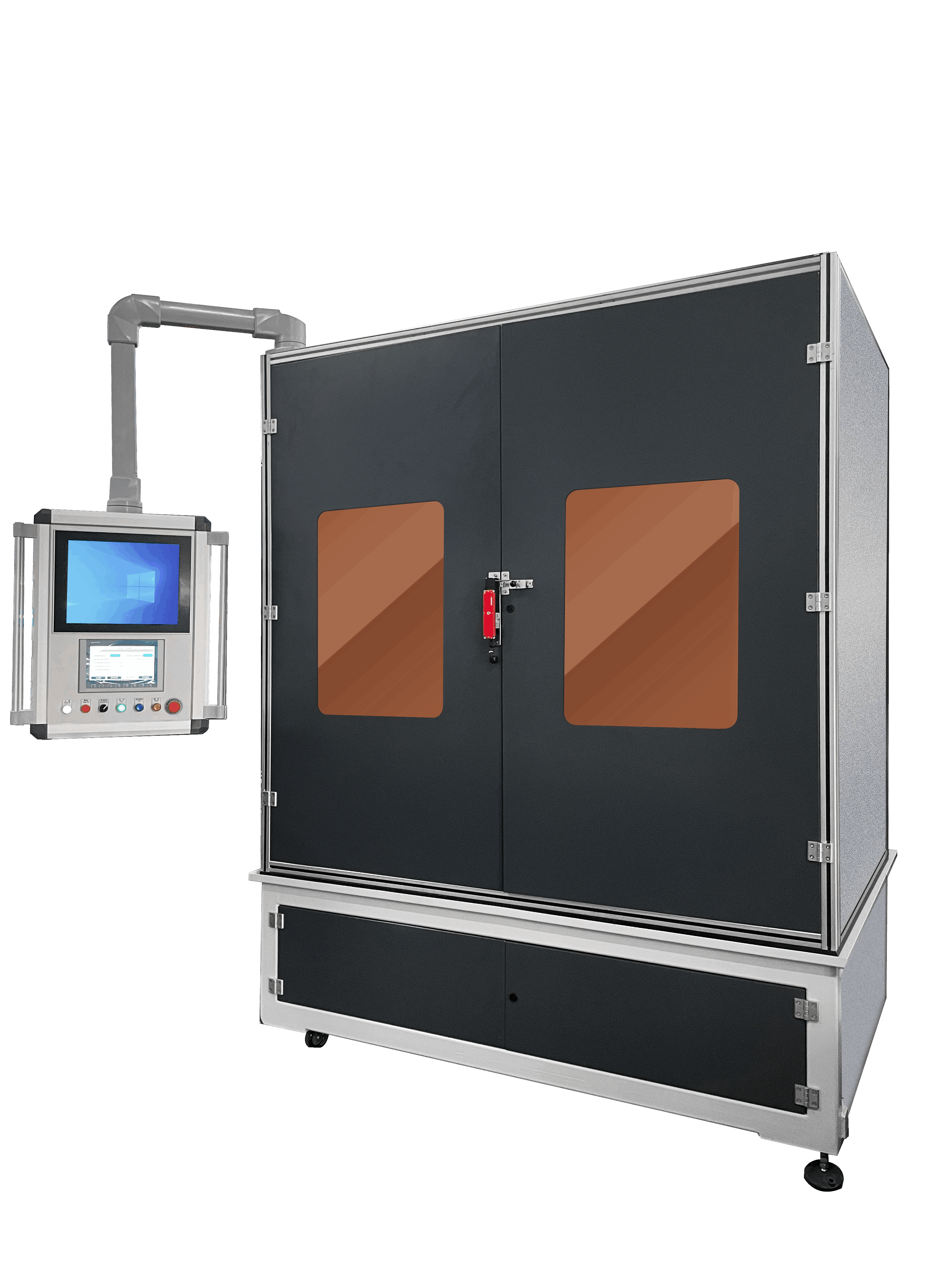

滚针外观缺陷光学自动检测设备(Choyo-R21)

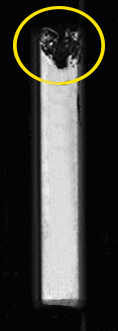

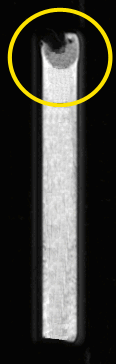

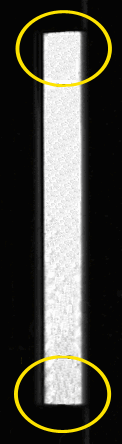

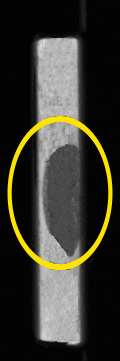

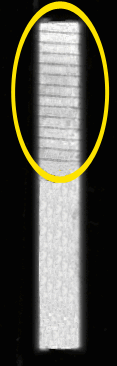

The optical automatic detection equipment for needle roller appearance defects is used for 360° appearance defect inspection of bearing needle rollers. It can detect defects such as wear, rotten spots, collapse, blade marks and other defects on the outer rolling surface, as well as the measurement and tolerance of needle roller length. Sorting. The inspection speed can reach 60,000pcs/h, and high-speed appearance inspection can be applied to wired appearance inspection. The equipment integrates dimensional measurement and out-of-tolerance elimination functions at the same time, which can effectively eliminate length out-of-tolerance.

Machine vision

Machine vision 轴承滚子

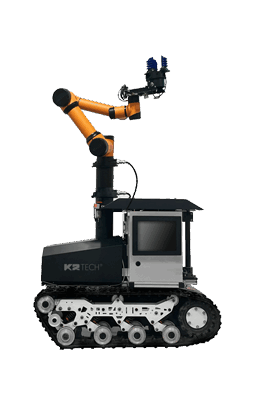

轴承滚子 Enameled wire 滚针外观缺陷光学自动检测设备(Choyo-R21) Robot for Optical Automatic Detection of Large Roller Appearance Defects Aligning roller轴承外观缺陷光学自动检测设备 超Robot for Optical Automatic Detection of Large Roller Appearance Defects 套圈外观缺陷光学自动检测设备 轴承防尘盖外观缺陷光学自动检测设备 轴承成品外观缺陷光学自动检测设备 钢球外观缺陷光学自动检测设备 滚子自动上料机 滚子在线雾化涂油机 滚子在线清洗烘干机

Enameled wire 滚针外观缺陷光学自动检测设备(Choyo-R21) Robot for Optical Automatic Detection of Large Roller Appearance Defects Aligning roller轴承外观缺陷光学自动检测设备 超Robot for Optical Automatic Detection of Large Roller Appearance Defects 套圈外观缺陷光学自动检测设备 轴承防尘盖外观缺陷光学自动检测设备 轴承成品外观缺陷光学自动检测设备 钢球外观缺陷光学自动检测设备 滚子自动上料机 滚子在线雾化涂油机 滚子在线清洗烘干机