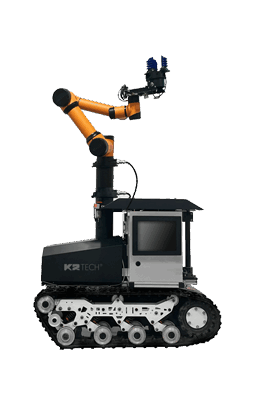

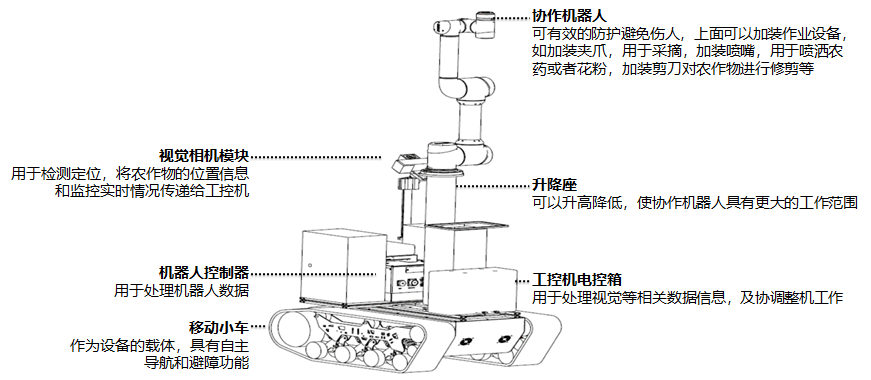

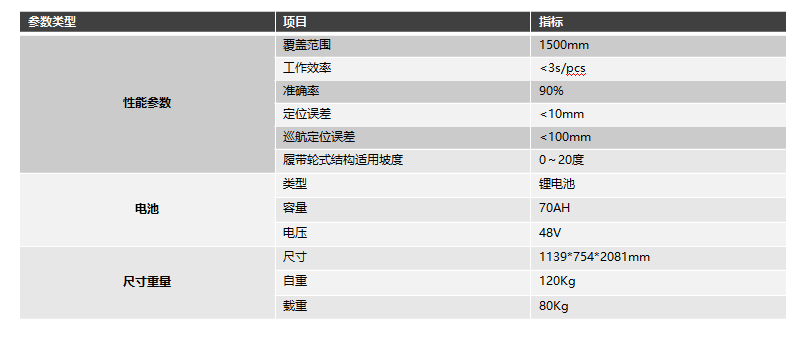

Intelligent fruit picking robot

In fruit and vegetable production operations, the picking and harvesting process accounts for about 40% of the entire operation. The traditional manual picking method is basically a labor-intensive operation with high labor intensity. It is affected by weather and sunCaton&Hera time restrictions. It not only has low labor efficiency, but also affects the quality of work. There is no guarantee, and the safety hazards during the picking process cannot be ignored. The emergence of unmanned picking robots solves the current difficulties faced by fruit picking, realizes farmland harvest automation, can adapt to environmental changes, ensures work efficiency, and is in line with the development of the fruit industry. need.

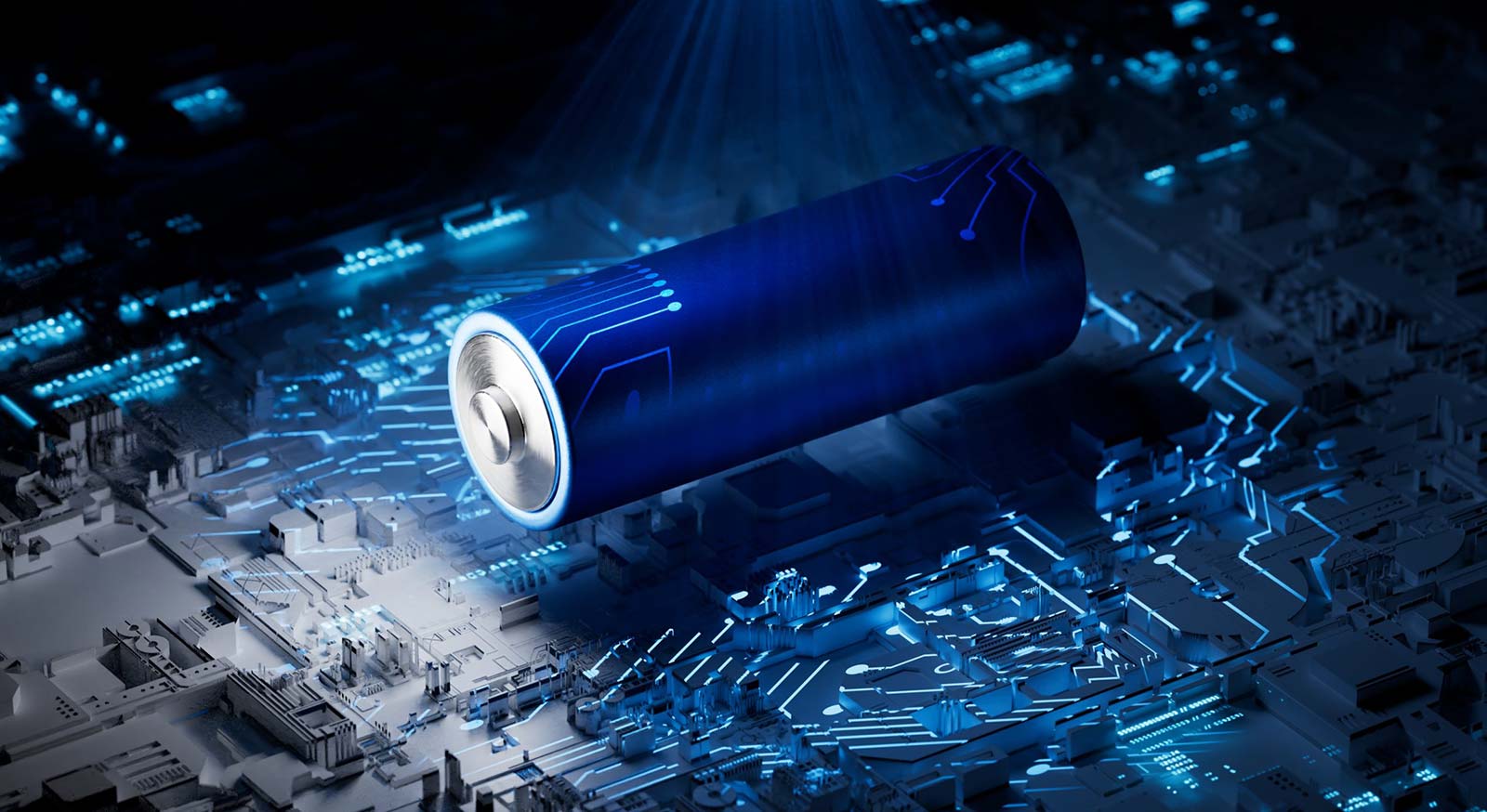

Machine vision

Machine vision 轴承滚子

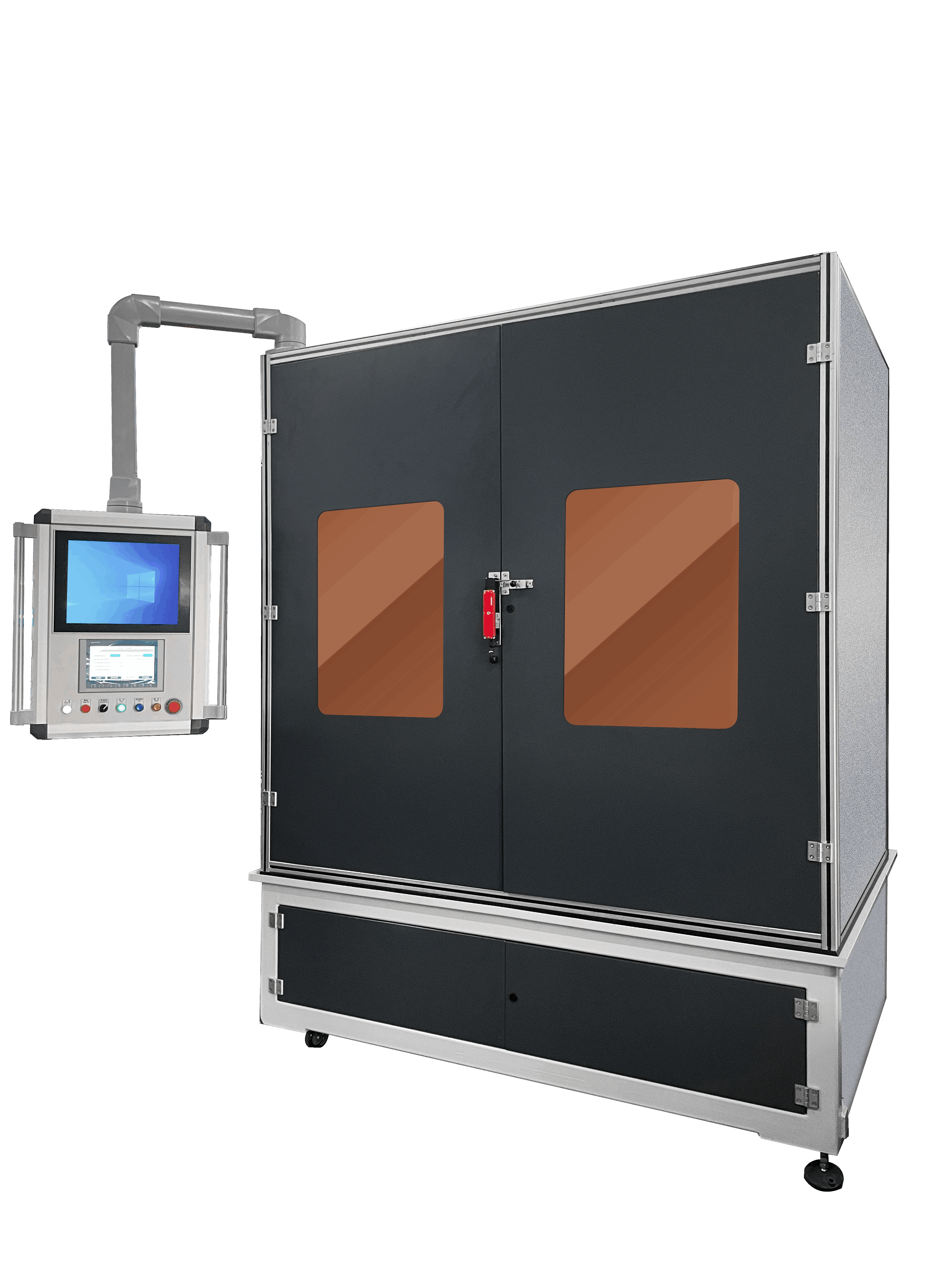

轴承滚子 Enameled wire 滚针外观缺陷光学自动检测设备(Choyo-R21) Robot for Optical Automatic Detection of Large Roller Appearance Defects Aligning roller轴承外观缺陷光学自动检测设备 超Robot for Optical Automatic Detection of Large Roller Appearance Defects 套圈外观缺陷光学自动检测设备 轴承防尘盖外观缺陷光学自动检测设备 轴承成品外观缺陷光学自动检测设备 钢球外观缺陷光学自动检测设备 滚子自动上料机 滚子在线雾化涂油机 滚子在线清洗烘干机

Enameled wire 滚针外观缺陷光学自动检测设备(Choyo-R21) Robot for Optical Automatic Detection of Large Roller Appearance Defects Aligning roller轴承外观缺陷光学自动检测设备 超Robot for Optical Automatic Detection of Large Roller Appearance Defects 套圈外观缺陷光学自动检测设备 轴承防尘盖外观缺陷光学自动检测设备 轴承成品外观缺陷光学自动检测设备 钢球外观缺陷光学自动检测设备 滚子自动上料机 滚子在线雾化涂油机 滚子在线清洗烘干机