Smart glasses

In the field of industrial manufacturing and maintenance, it often happens that faults occur and cannot be eliminated in time because engineers cannot rush to the scene at the first time. However, smart glasses come in perfectly. Operators at the fault site only need to wear AR smart glasses and scan 3D images from the first perspective and upload them to the cloud. Expert engineers at a distance can accurately grasp the situation at the scene. Analyze the cause of the fault and guide the remote operator to perform on-site maintenance work.

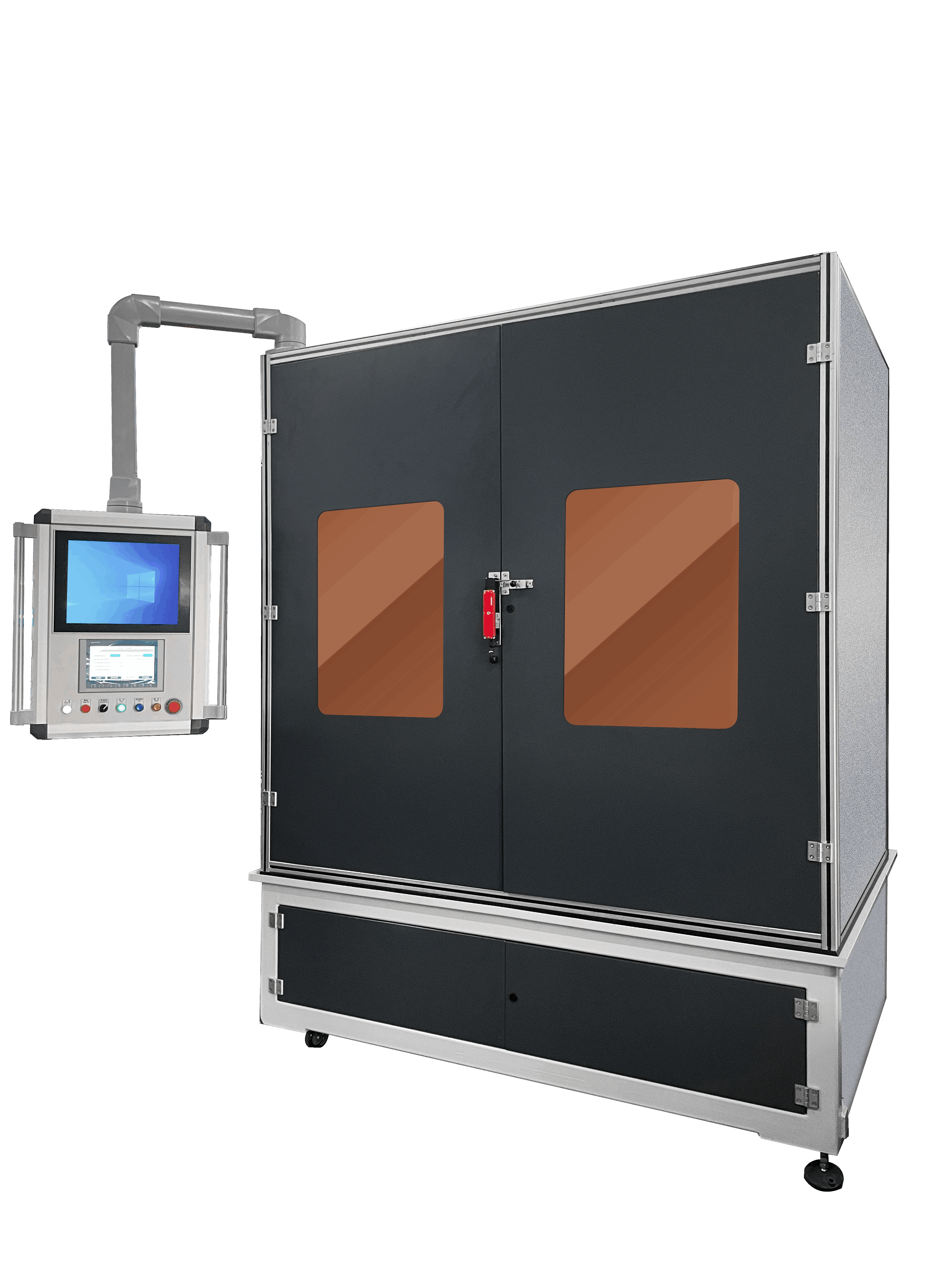

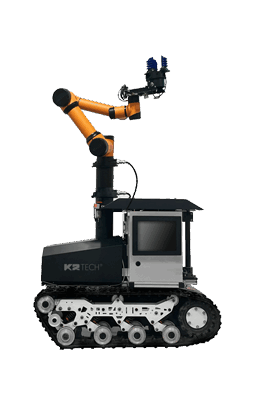

Machine vision

Machine vision 轴承滚子

轴承滚子 Enameled wire 滚针外观缺陷光学自动检测设备(Choyo-R21) Robot for Optical Automatic Detection of Large Roller Appearance Defects Aligning roller轴承外观缺陷光学自动检测设备 超Robot for Optical Automatic Detection of Large Roller Appearance Defects 套圈外观缺陷光学自动检测设备 轴承防尘盖外观缺陷光学自动检测设备 轴承成品外观缺陷光学自动检测设备 钢球外观缺陷光学自动检测设备 滚子自动上料机 滚子在线雾化涂油机 滚子在线清洗烘干机

Enameled wire 滚针外观缺陷光学自动检测设备(Choyo-R21) Robot for Optical Automatic Detection of Large Roller Appearance Defects Aligning roller轴承外观缺陷光学自动检测设备 超Robot for Optical Automatic Detection of Large Roller Appearance Defects 套圈外观缺陷光学自动检测设备 轴承防尘盖外观缺陷光学自动检测设备 轴承成品外观缺陷光学自动检测设备 钢球外观缺陷光学自动检测设备 滚子自动上料机 滚子在线雾化涂油机 滚子在线清洗烘干机